ACTIVITES

Our Company uses in its workings any plastic material, to obtain pipes, tanks, manufactured coatings and anything else required, in reinforced bi-laminar material.

Based on the Customer's technical specifications and in accordance with current international regulations, we are able to design, and then build, any plant equipment necessary for the most complex industrial process. We have no application limits in the most varied industrial sectors: from the chemical to the pharmaceutical, from the petrochemical to the environment. Our equipment can be coated in fiberglass (FRP), which acts as a structural element as well as protection from wear and weathering in outdoor applications. We carry out the assembly of the equipment or the installation of the pipes to give the customer the commissioned finished, certified and fully functional plant; we are present in various industrial companies also as maintenance technicians, both of plants of our. production that does not.

We carry out any type of equipment that is a concentrate of advanced technology and unparalleled manufacturing art.

PIPE PRODUCTION AND INSTALLATION

Our Company works in plastic pipes (PP, PVC, PVDF, FRP, MFA, E-CTFE, FEP, PFA, PTFE) to obtain pipes in reinforced bi-laminar material. The choice of the internal liner and the subsequent external covering is made on the basis of the customer's technical specifications and the production is carried out according to the current legislation respecting the various international standards.

These pipes are delivered in sketches and installed on site, creating special "pipe racks" for support.

TANK PRODUCTION AND INSTALLATION

Our company designs, builds and installs tanks and equipment for the storage of corrosive products. In such applications it is fundamental to choose the most suitable material as the technical solutions can be multiple.

The available geometries can be the most varied, but certainly the most widespread types are those with circular section with installation or horizontal on saddles or vertical.

Their design and construction follow what is established by current legislation on the subject, in particular for the implementation follows what is established by current legislation, especially for the construction of reinforced tanks in FRP we refer to the European standard EN 13121- 3: 2016.

The types of tanks we manufacture can therefore be grouped as follows:

Plastic tanks (PP, PVC, or FRP).

Steel tanks internally lined with plastic (PP, PVDF, MFA, E-CTFE, FEP, PFA, PTFE).

FRP tanks with thermoplastic material (PP, PVDF, MFA, E-CTFE, FEP, PFA, PTFE).

ANTI-CORROSIVE COVERINGS

FRP COVERINGS

The fiberglass coatings are distinguished by the type of resin used and the type of reinforcement used. In any case, the processing consists in the laying of specific fibrous fabrics on the substrate to be coated and in the subsequent impregnation of the fibers with the resin. Depending on the application, the necessary thickness of the coating is chosen and the fabrics are applied until the final thickness is reached. The preparation of the surface preparation is of fundamental importance to achieve the excellent final result. However, we give a brief overview of the most commonly used resins in the anti-corrosion sector:

BISPHENOLIC SYSTEM: resin of the family of polyesters with high chemical resistance. They can be used to protect against the aggression of almost all acids at temperatures even above 100 ° C

EPOXY SYSTEM: resin with high mechanical properties with excellent adhesion characteristics to the substrate.

VINYL ESTERINE SYSTEM: resin also belonging to the family of polyesters, with mechanical properties comparable to that of epoxy resin but having a higher resistance to temperatures.

FURANIC SYSTEM: highly technical resin, to be applied where the operating temperatures and chemical concentrations do not allow the use of other materials.

As for the type of fibers, we can briefly list what is needed:

GLASS FIBERS: Supplied in the form of MAT or STOVE fabrics in various weights. They have the function of imparting stiffness and mechanical resistance to the coating.

SYNTHETIC FIBERS: Provided in the form of low-weight fabrics. They give less mechanical rigidity when compared to glass fibers, but guarantee excellent mechanical resistance even with particularly aggressive acids.

CARBON FIBERS: Provided with a unidirectional type, they impart a high rigidity to the product.

THERMOPLASTIC COATINGS

PVC COVERINGS: For those products and applications for which fiberglass is not recommended, and in cases where resistance to high temperatures is not required, coatings with semi-rigid PVC sheets are made, with different thicknesses depending on the use case .

PP COATINGS: Usable when the application requires in addition to the greater chemical resistance, even a rather high temperature. Also in this case, the PP is applied in the form of semi-rigid sheets.

FLUORURATED MATERIALS: Materials such as PVDF, E-CTFE, MFA, FEP, PFA and PTFE are used for highly burdensome applications, where the concentration of the acid is high and where the operating temperature is above 80 ° C. These materials are applied in the form of plates in various materials welded to each other.

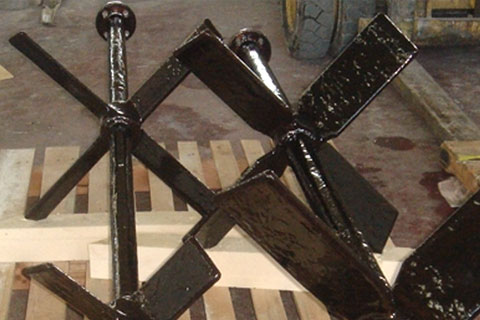

SPECIAL DRAWINGS IN DRAWING

Our Company produces "custom" custom-made products. On request in fact of the customer, our technical staff carries out the industrialization of the product in order to realize it in plastic materials, perhaps reinforced, or with fluorinated materials specially selected for the application.

DESIGN AND INSTALLATION OF PLANTS

Our Company manufactures transfer plants for "turnkey" acid solutions. These plants are generally made up of tanks, pumping units and supply lines. The sizing, the choice of materials and the operating mode of the plant are developed on the basis of technical specifications elaborated or discussed with the Customer. In fact, once the system has been completed, the various measuring instruments necessary to guarantee the operation and reliability of the system are installed. Our The company also provides the supervision software that, in addition to allowing the management of the plant in automatic mode, continuously monitors the various equipment, providing the operator with the necessary information on the status of the plant.